Biogas

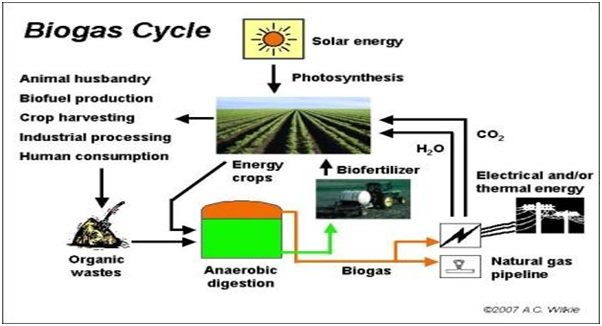

Biogas typically refers to a gas produced by the breakdown of organic matter in the absence of oxygen. It is a renewable energy source, like solar and wind energy. Furthermore, biogas can be produced from regionally available raw materials, recycled waste, and is environmentally friendly. Biogas is produced by the anaerobic digestion or fermentation of biodegradable materials such as manure, sewage, municipal waste, green waste, plant material, and crops. Biogas comprises primarily methane (CH4) and carbon dioxide (CO2) and may have small amounts of hydrogen sulphide (H2S), moisture and siloxanes. Biogas is produced by the anaerobic digestion or fermentation of biodegradable materials such as manure, sewage, municipal waste, green waste, plant material, and crops. Biogas comprises primarily methane (CH4) and carbon dioxide (CO2) and may have small amounts of hydrogen sulphide (H2S), moisture and siloxanes.

Production

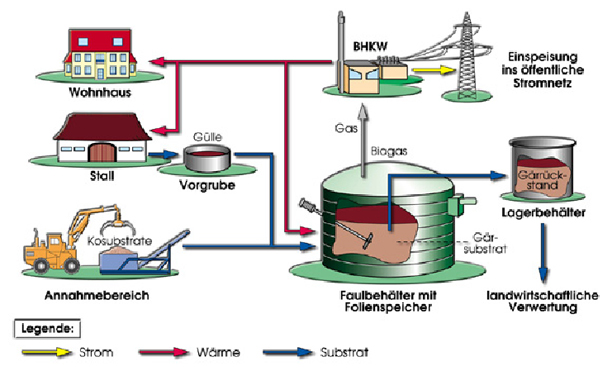

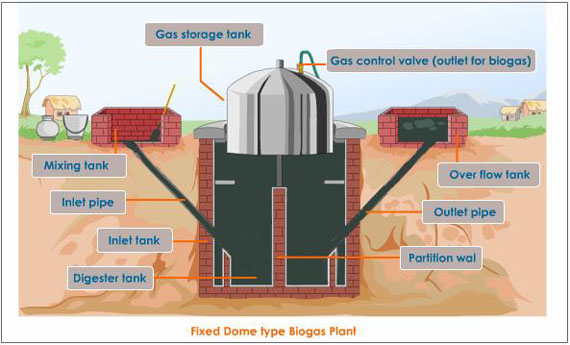

Biogas can be compressed, much like natural gas, and used to power motor vehicles. In the UK, for example, biogas is estimated to have the potential to replace around 17% of vehicle fuel. Biogas is a renewable fuel so it qualifies for renewable energy subsidies in some parts of the world. Biogas can also be cleaned and upgraded to natural gas standards when it becomes bio methane.Bio gas is practically produced as landfill gas (LFG) or digested gas. A bio gas plant is the name often given to an anaerobic digester that treats farm wastes or energy crops. Bio gas can be produced using anaerobic digesters. These plants can be fed with energy crops such as maize silage or biodegradable wastes including sewage sludge and food waste. During the process, as an air-tight tank transforms biomass waste into methane producing renewable energy that can be used for heating, electricity, and many other operations that use any variation of an internal combustion engine, such as GE Jenbacher gas engines. There are two key processes: Mesophilic and Thermophilic digestion. In experimental work at University of Alaska Fairbanks, a 1000-litre digester using psychrophiles harvested from "mud from a frozen lake in Alaska" has produced 200–300 liters of methane per day, about 20–30% of the output from digesters in warmer climates. Landfill gas is produced by wet organic waste decomposing under anaerobic conditions in a landfill. The waste is covered and mechanically compressed by the weight of the material that is deposited from above. This material prevents oxygen exposure thus allowing anaerobic microbes to thrive. This gas builds up and is slowly released into the atmosphere if the landfill site has not been engineered to capture the gas. Landfill gas is hazardous for three key reasons. Landfill gas becomes explosive when it escapes from the landfill and mixes with oxygen. The lower explosive limit is 5% methane and the upper explosive limit is 15% methane. The methane contained within biogas is 20 times more potent as a greenhouse gas than is carbon dioxide. Therefore, uncontained landfill gas, which escapes into the atmosphere, may significantly contribute to the effects of global warming. In addition, landfill gas impact in global warming, volatile organic compounds (VOCs) contained within landfill gas contribute to the formation of photochemical smog.

Biogas formation

Composition

| Typical composition of biogas |

| Compound |

Molecular formula |

% |

| Methane |

CH4 |

50–75 |

| Carbon dioxide |

CO2 |

25–50 |

| Nitrogen |

N2 |

0–10 |

| Hydrogen |

H2 |

0–1 |

| Hydrogen sulphide |

H2S |

0–3 |

| Oxygen |

O2 |

0–0 |

The composition of biogas varies depending upon the origin of the anaerobic digestion process. Landfill gas typically has methane concentrations around 50%. Advanced waste treatment technologies can produce biogas with 55–75% methane, which for reactors with free liquids can be increased to 80-90% methane using in-situ gas purification techniques As-produced, biogas also contains water vapor. The fractional volume of water vapor is a function of biogas temperature; correction of measured gas volume for both water vapor content and thermal expansion is easily done via simple mathematics, which yields the standardized volume of dry biogas.

Biogas upgrading

Raw biogas produced from digestion is roughly 60% methane and 29% CO2 with trace elements of H2S, and is not high quality enough to be used as fuel gas for machinery. The corrosive nature of H2S alone is enough to destroy the internals of a plant. The solution is the use of biogas upgrading or purification processes whereby contaminants in the raw biogas stream are absorbed or scrubbed, leaving more methane per unit volume of gas. There are four main methods of biogas upgrading; these include water washing, pressure swing absorption, selexol absorption, and amine gas treating. The most prevalent method is water washing where high pressure gas flows into a column where the carbon dioxide and other trace elements are scrubbed by cascading water-running counter-flow to the gas. This arrangement could deliver 98% methane with manufacturers guaranteeing maximum 2% methane loss in the system. It takes roughly between 3-6% of the total energy output in gas to run a biogas upgrading system.

The first Biogas Bottling Plant towards commercialization in India

Keeping in view the energy shortage in the country there is a need to tap biomass resources such as cattle dung, kitchen waste, agricultural waste etc for generation of biogas through the involvement of entrepreneurs and industries to set up decentralized biogas based energy infrastructure in the country, at the potential sites where biomass available is plenty. Under technology demonstration of new RDD&D Policy of Ministry of New and Renewable Energy (MNRE), the Ministry took up a new initiative for bottling of biogas to demonstrate an Integrated Technology-package in entrepreneurial mode on medium size (200-1000 cum/day) mixed feed biogas-fertilizer plants (BGFP) for generation, purification/enrichment, bottling and piped distribution of biogas. Installation of such plants aims at meeting stationary and motive power, cooling, refrigeration and electricity needs in addition to cooking and heating requirements. There could be a huge potential of installation of medium size biogas-fertilizer plants in the country. Under the demonstration phase, the Ministry is providing a central financial assistance of 50 percent of the cost (excluding cost of land) for a limited number of such projects for implementation following an entrepreneurial mode on Built, Own and Operate (BOO) and re-imbursement basis.The proposals are proposed to be evaluated by experts and considered by Technology Demonstration Appraisal Committee of the Ministry. Recommended projects are to be implemented, operated and owned by the concerned industries/entrepreneurs/ project developers. The MNRE share will be released only after successful commissioning of BGFP projects, receipt of joint inspection report from committee & required statutory clearance/permissions etc. During the year, various meetings have been organized by the MNRE and committees set up for streamlining necessary approvals from Petroleum and Explosives Safety Organization (PESO), DIPP, Ministry of Commerce and Industry, Bureau of Indian Standard (BIS), Central Pollution Control Board (CPCB) and Ministry of Environment and Forests.